testing the hardness of annealed copper|copper bending and annealing : factories They complement the Mechanical Properties of Copper and Copper Alloys . web67K Followers, 55 Following, 181 Posts - See Instagram photos and videos from 조지아 조수아 (@ziasua_99)

{plog:ftitle_list}

Resultado da Primeiro as Senhoras. 109. UEFA Women´s Nations League. Grp.3. Ilhas Faroé. Grp.5. Grp.2. Grp.1. Cazaquistão. Grp.2. Lituânia. Atlético CP. .

They were tested by the Cryogenics Div., National Bureau of Standards, for the copper and brass industry to check tensile strength, notch tensile strength, Youngs modulus, and impact properties at temperatures down to 4 K (-454 F).

The basic properties of copper alloys are largely influenced by the properties of .This section displays photo micrographs of commercially important and/or .

They complement the Mechanical Properties of Copper and Copper Alloys .

Copper and copper alloy powders have been used in industrial applications for .In particular, the Copper & Copper Alloy Corrosion Resistance Database is .Types of Copper and Properties. The copper most commonly used for sheet .

This experiment demonstrates the process of work hardening in a copper, that is, hardening the metal by deformation. If an appropriate furnace is available, it also demonstrates the softening .Types of Copper and Properties. The copper most commonly used for sheet and strip applications complies with ASTM B370. It consists of 99.9 percent copper, and is available in . The Mohs Hardness Scale is a widely recognized and simple scale for measuring the scratch resistance of various minerals. Created by Friedrich Mohs, a German geologist, in 1812, it remains a standard in geology, .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. The Rockwell test is generally easier to perform and more accurate than other hardness methods.How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. The hardness of a material refers to the materials ability to resist deformation, indentation or scratches. It is a measure of the materials .The observed effect of strain hardening on the correlations may be due to wide differences in cold-working that occurs before hardness testing and during the test itself for annealed .hardness tester, tensile testing machine and simple deflection rig and understand the procedures employed to determine the mechanical properties resulting from different annealing .

Annealing at high temperatures can remove the effects of strain-hardening via microstructural changes that generally occur in the following sequence: recovery, recrystallization and grain . Testing was carried out on a screw driven machine (JJ Lloyd L2000R, research grade) of 30 kN capacity. One set of tests was carried out at a displacement rate .

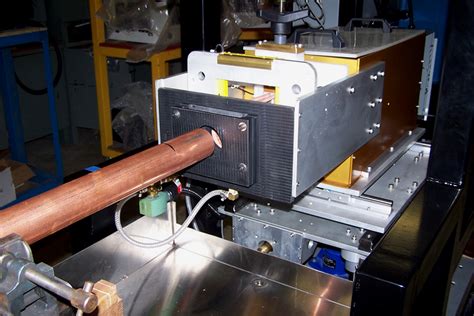

copper wire annealing

Annealing is a heat treatment process that changes the physical and sometimes also the chemical properties of a material to increase ductility and reduce the hardness to make it more workable. . other metals can also benefit from the .Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. Brinell . Table . Hardness values for cold rolled annealed steel. Cold rolled annealed steel Rockwell B Test Brinell 10/500 Hardness Test Average 99.7 227.5 Conversion table value 95 220 Table . Hardness values for aluminum. 6061 Aluminum Rockwell B Test Brinell 10/500 Hardness Test 1.4 Electrical conductivity, when evaluated with eddy current instruments, is usually expressed as a percentage of the conductivity of the International Annealed Copper Standard (% IACS) or Siemens/meter (S/m). The conductivity of the Annealed Copper Standard is defined to be 0.58 × 10 8 S/m (100 % IACS) at 20°C.

testing lead hardness bullets

The micro-hardness keeps at 1.25 GPa constantly when annealed at 473 K till 400 min, and slightly decreases to 1.15 GPa when annealed at 523 K for 600 min due to dislocation recovery, as revealed . For instance, metals with high thermal conductivity, like copper, can be annealed faster than those with low thermal conductivity, like stainless steel. . This results in a material with improved ductility and reduced hardness. Each of these annealing processes serves a specific purpose and is used in various applications across the .

Hardness testing is one of the most common quality control checks performed. It is often used to determine . F Annealed copper alloys, thin soft sheet metals. G Phosphorous bronze, beryllium copper, malleable irons and materials softer than HRG 92. H Aluminum, lead, and zinc.

testing lead hardness for bullet casting

copper bending and annealing

Annealing is a heat treatment of metals or alloys that restores some of the material’s original physical properties. In particular, it increases ductility and decreases hardness. Annealing is done by raising the temperature of the metal to above its recrystallization temperature but below its melting point.The cylindrical sample was used in the test. Dimension of the sample was 20mm in height and 18.5mm in diameter. . Hardness of original pure copper was 107 HV while hardness of annealed pure .calculating the area under the stress strain curve produced during a tensile test. (2) Annealing at high temperatures can remove the effects of strain-hardening via . Here a hardness tester can be used if available. If not a scratch test may used. . Annealed 300°F (149°C) Annealed 600°F (316°C) Copper As Elongated grains seen Annealed .

O32 Hot Extruded and Temper Annealed O40 Hot Pierced and Annealed O50 Light Anneal O60 Soft Anneal O61 Annealed O65 Drawing Anneal O68 Deep Drawing Anneal O70 Dead Soft Anneal O80 Annealed to Temper— 1⁄8 Hard O81 Annealed to Temper— 1⁄4 Hard O82 Annealed to Temper— 1⁄2 Hard 6.1.2 Annealed to Meet Nominal Average Grain Size, OS .

The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method . Annealed copper alloys, and thin soft sheet metals: HRG: Ball, 1.588 mm (1/16 inch) 98.07 N (10 kgf) 1471 N (150 kgf) Malleable irons, copper-nickel-zinc and cupronickel alloys: HRH: Ball, 3.175 mm (1/8 inch) Olokode et al. (2008) also investigated the effects of process annealing on the mechanical properties of cold worked copper wires and concludes that the hardness of copper during cold drawing . Pick up the annealed copper with a pair of pliers. At this point, the copper will be incredibly hot, so you obviously cannot pick it up with your bare hands. So, slip 1 of the jaws of a pair of pliers under the edge of the copper bar or pipe, squeeze the pliers tightly shut, and pick up the annealed copper.

Generally, hardness and strength decrease and ductility (elongation) increases with increasing grain size. An exception to this would exist where the material is very thin and the grain size is very large resulting in very few grains through .

Annealed metals are often easier to weld, as the process reduces hardness and brittleness, leading to better weld quality and reduced risk of cracking. Preparation for Further Processing Annealing is often used as a .Generally, hardness and strength decrease and ductility (elongation) increases with increasing grain size. An exception to this would exist where the material is very thin and the grain size is very large resulting in very few grains through .

The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters. Annealed copper is a special type of copper alloy that has been processed through heating and cooling to increase its malleability and workability. In this article, we’ll break down all the basics about annealed copper, including its properties, uses and composition. . Hardness, Rockwell: 40: 40: Annealed Copper Uses.Annealing the copper requires a high temperature. Copper melts at 1357Kelvin and annealing generally occurs at greater than half the melting point in degrees K; even higher temperature causes faster annealing (but not past the melting temperature, of course). Typical temperature to use is 400C or 700F. Annealing causes the structure toconductivity of the International Annealed Copper Standard (IACS), of materials shall be not less than those given in Table 3. 6 Methods of test 6.1 Vickers hardness test The Vickers hardness test shall be carried out with a 300 N load in accordance with ISO 6507-1. 6.2 Electrical properties

copper annealing worksheet

Stress relief annealing can also improve the elasticity and strength of cold formed brass, zinc white copper and phosphor bronze. The annealing time of general alloy is 1-3 h, and that of beryllium bronze is 15-20 min. General copper alloy elastic material strengthening and heat treatment: some copper alloy through cold plastic deformation and .Chemical Composition; Elements; Cu (1,2,3) Pb Zn Fe P Ag As O Sb Te (1) This is a high conductivity copper which has, in the annealed condition a minimum conductivity of 100% IACS except for Alloy C10100 which has a minimum conductivity of 101% IACS.

Each hardness testing method has its characteristics and range of applications: The Brinell hardness test is suitable for various materials, especially annealed, normalized, quenched and tempered steel, cast iron, and non-ferrous metals. The Rockwell hardness test is suitable for a wide range of materials, using a smaller indenter for measurements.The degree of annealing is controlled by temperature and time, copper wire is used with different degrees of annealing depending on the application. Hard drawn copper has significantly higher tensile strength than soft annealed copper and is used as overhead wire whereas the soft annealed copper is flexible and has somewhat improved . Vickers hardness tests were conducted on samples of copper and aluminium in a cold rolled or annealed condition to determine the apparent hardness variation in the load range 15 g to 20 kg. The variation was greatest for the soft specimens. Lubrication with an extreme-pressure lubricant was effective in reducing the hardness values to a virtually constant level .

Mohs hardness [1] Vickers hardness (MPa) [1] Brinell hardness (MPa) [1] Brinell hardness (MPa) [note 1] [2] 3: Li: lithium: 0.6 ~2: 5: 4: Be: . copper: 3: 343–369: 235–878: 520 30: Zn: zinc: 2.5: 300: 327–412: 480–520 31: Ga: gallium: 1.5: 500: 56.8–68.7: 32: Ge: . Mohs scale of mineral hardness; Vickers hardness test; Brinell .

webVídeos da Dani Russo no Onlyfans 294.408 00:06. Vídeo da Dani Russo pelada COM TARJA 221.904 00:17. Vídeos gratis da Dani Russo rebolando de calcinha 60.775 00:23.

testing the hardness of annealed copper|copper bending and annealing